Loading

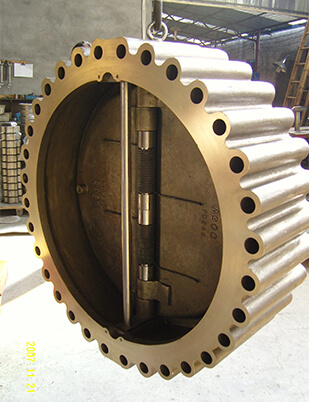

Dual Plate Check Valves

Valvemark has an extensive experience in supplying of throughout the hydrocarbon, energy and process industries across the world.

2” - 56“

Up to 2500#

API 6D / 594

Available Types

- Wafer Type

- Solid Lug Type

- Double Flange type

- Hub End type

- Butt weld end type

Cryogenic Service

Almost all Dual Plate Check Valve types can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer, down to Cryogenic -196°C.

Technical Specifications

| Size Range | 2” up to 56“ (DN 50 up to DN 1400) |

|---|---|

| Pressure Rating | ASME 150# to 2500# |

| Design Standard | API 6D, API 594, MESC SPE 77 / 133 |

| Test Standard | API 598, API 6D, ISO 5208 MESCSPE 77/133, ISO 15848-1&2 Bs6364 |

| Construction | Dual Plate, Soft and Metal Seated |

Swing Type Bolted Bonnet

Valvemark has an extensive experience in supplying of Piston, Swing, Tilting Disc and Non-Slam Check Valves for use in the hydrocarbon, energy and process industries.

½” - 56“

Up to 2500#

API 602 / 6D

Available Types

- Swing Type Bolted Bonnet

- Piston type check valves

- Non-Slam Check Valves

- Tilting Disc Pressure Seal

- Nozzle type

Cryogenic Service

Almost all Check Valve can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer, down to Cryogenic -196°C.

Technical Specifications

| Size Range | ½” up to 56“ (DN 15 up to DN 1400) |

|---|---|

| Pressure Rating | ASME 150# to 2500# |

| Design Standard | API 602, API 6D, MESC SPE 77 / 132, BS 1868, DIN 3356, ISO15761 |

| Test Standard | API 598, API 6D, MESC 77/132, ISO 5208, ISO15848-1&2, Bs6364 |

| Construction | Bolted Cover / Pressure Seal Bonnet, Lift Check, Swing Check, Piston Check, Tilting Disc, Non–Slam |

Material Selection

Our valves are available in a wide range of materials to suit various corrosive and non-corrosive environments.

Standard Materials

- Carbon Steels

- Low Temperature Carbon Steel

- Martensitic Steels

- Austenitic Stainless Steel

Exotic Alloys

- Duplex & Super Duplex Stainless

- Nickel Alloys & Inconel

- Titanium Alloy

- Hastelloy & Nickel Aluminum Bronze

- Carbon Steel with CRA Overlay